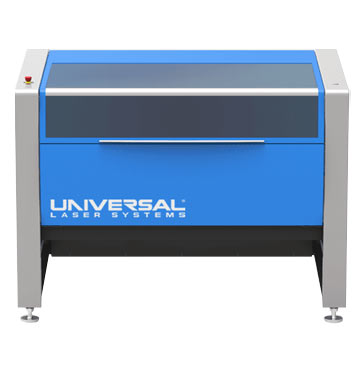

VLS Ultra Model R9000

VLS Ultra Model R9000

Platform Overview

The ULTRA R9000 platform offers laser material processing for a wide range of materials. It is designed and ideally suited for material processing in manufacturing, research and development, academic research, and prototyping environments. With its unique modular architecture, customizable solutions can be easily reconfigured with a wide array of options for enhancing performance, capability, and safety to complete the perfect solution to meet present and future business needs.

Download Brochure

Platform Specifications

| Material Processing Envelope (X,Y,Z) | 48 x 24 x 12 in. (1219 x 610 x 305 mm) |

| Maximum Effective Raster Material Processing Speed | >200 in./sec (5080 mm/sec) [Requires SuperSpeed™ operation] |

| Multiple Laser Support | UP TO 2 LASER SOURCES CAN BE USED INDIVIDUALLY OR IN COMBINATION Laser Sources Available CO2: 10.6 μm 10, 30, 40, 50, 60, 75, and 150 watt laser sources CO2: 9.3 μm 30, 50, and 75 watt laser sources Fiber: 1.06 μm 50 watt laser source Laser Sources Combinations Up to (2) CO2 laser sources (10-150 watts) or up to (1) CO2 laser sources (10-150 watts) and up to (1) permanently mounted Fiber laser source SUPPORTS RAPID RECONFIGURATION OF CO2 LASERS |

| Maximum Laser Power |

CO2: 300 watts Fiber: 50 watts |

| System External Dimensions |

Width: 71.0 in. (1803 mm) Depth: 44.0 in. (1118 mm) Height: 48.0 in. (1211 mm) |

| Weight | 500 lbs (227 Kg) |

| Power Requirements | 220V-240V/16A (300 Watt configuration requires high power kit and 25A) |

| Exhaust Requirements | – Intelligent Air Filtration (UAC 4000) or External Exhaust Blower Capable of >700 CFM at 6 in. – WG Static Pressure (1190 m3/hr. at 1.5 kPa) – 6 in. (152mm) Exhaust Port |

| Computer Requirements | – Minimum: Intel I3 processor (or equivalent) with at least 8 Gb of memory, Windows 10 operating system, and connection to laser system with USB cable. – Computer is not required if configured with available 21” Touch Screen Control Panel |

| Laser Safety Classification | Class 1 for material processing lasers Class 2 overall due to red laser pointer Can convert to Class 4 with available Class 4 module |

| NOTES | Weight is approximate and varies with laser source selection * Available feature |

The ULTRA R9000 platform has a materials processing envelope of 48 x 24 in (1219 x 610 mm), with support for materials with a thickness up to 12 in (305 mm).

Configure the customizable ULTRA R9000 platform with up to two laser sources consisting of two interchangeable CO2 lasers or one CO2 laser and one fiber laser. When the platform is configured with two lasers users can take advantage of MultiWave Hybrid™ technology enabling up to two of three wavelengths from 9.3 µm, 10.6 µm, and 1.06 µm – to be simultaneously combined into a single coaxial beam. Each spectral component of the beam is independently controlled and can be modulated in real time.

Major features and options include multiple laser support, rapid laser beam positioning, precision material-independent autofocus, controllable laser power density, automation interface, multi-camera vision & registration, over temperature detection, and support for fire suppression.

Ultra Series Options

Multi-Camera Vision & Registration *

A patent pending feature that provides an augmented reality user interface by superimposing design files on images of the material placed on the material support surface and captured by multiple cameras built into the laser system.

The AR user interface facilitates precise alignment of design files using controls that allow the design file to be positioned, rotated and scaled with real time visual feedback made possible through advanced machine vision algorithms.

This feature also supports traditional camera registration work flow using printed registration marks.

Precision Material Independent Autofocus

A motorized Z-axis and high-resolution touch sensor with repeatability of ± .005 in (125 μm).

SuperSpeed™ Technology *

A patented feature that produces two focal spots (one for each laser beam) to enable the system to deliver two independently controlled raster lines at a time. SuperSpeed requires a laser system equipped with two CO2 lasers of the same wavelength and power.

Multi-Wave Hybrid™ Technology *

A patented technology that enables a combination of laser wavelengths (up to two wavelengths) to be focused to the same focal point within the same focal plane and used either sequentially or simultaneously.

Rapid Reconfiguration™

A patented technology that enables users to install and reinstall any supported ULS CO2 laser source onto any ULS laser system without tools or optical alignment to optimize laser processing for the widest variety of materials.

Intelligent Materials Database

A powerful and unique database that generates laser processing parameters for a wide variety of materials and laser system configurations. If the system configuration changes, the database automatically recalculates the parameter values.